- 1. Stainless steel material trays and drying chamber.

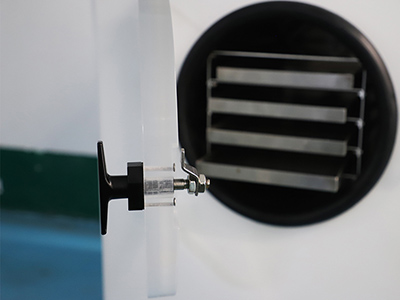

- 2. Transparent visible plexiglass door,can observe the lyophilization process of materials directly.

- 3. LCD touch screen, one button start. PLC system control, can set up programs and save different freeze drying formulas, one touch to run setted program for different samples.

- 4. USB interface can download freeze drying data for record.

- 5. USB interface can download freeze drying data for record.

DESCRIPTION

Lyophilization or freeze drying is a process in which water is removed from a product after it is frozen and placed under a vacuum, allowing the ice to change directly from solid to vapor without passing through a liquid phase. The process consists of three separate, unique, and interdependent processes; freezing, primary drying (sublimation), and secondary drying (desorption).

FEATURES

1. Perfect appearance, compact size;

2. Touch screen operation, one key to start, and automatic freeze drying process, easy and convenient;

3. Key components with imported brands, small noise, large capacity, high quality and high performance;

4. Advanced system, with low operating current and low energy consumption;

5. 304 stainless steel food tray and inside liner, safety and easy clean;

6. Transparent organic glass door, the direct observation of food processing

SPECIFICATIONS

|

Model |

LFD-4 |

|

Overall size WxDxH |

700*860*930mm |

|

Energy consumption |

1100W |

|

Power supply |

220V 50HZ |

|

Food tray area |

0.36㎡ |

|

Single batch of food |

4~6kg |

|

Tray size |

200*420mm |

|

No. of tray |

4pcs |

|

Space between tray |

45mm |

|

Gross weight |

150kg |

|

Condenser temperature |

≤-35°C |

|

Drying temperature |

-30°C ~+60°C |

|

Vacuum |

<15Pa |