This 10-12kg capacity freeze dryer is ideal for efficient preservation of food products, including fruits, vegetables, meats, and more. Utilizing advanced vacuum freeze-drying technology, it removes moisture while retaining the original nutrients, texture, and taste.

Key features include:

• High Capacity: Handles up to 10-12kg per batch, making it suitable for small-scale commercial use or research applications.

• Advanced Vacuum Technology: Ensures thorough and even drying, preserving the quality of the products.

• Versatile Applications: Suitable for food preservation, pharmaceutical materials, and lightweight storage solutions.

• Easy Operation: User-friendly controls with customizable drying cycles and temperature settings.

This freeze dryer is the perfect solution for businesses or individuals looking to extend the shelf life of food products while ensuring premium quality preservation.

- 1. Stainless steel material trays and drying chamber.

- 2. Transparent visible plexiglass door,can observe the lyophilization process of materials directly.

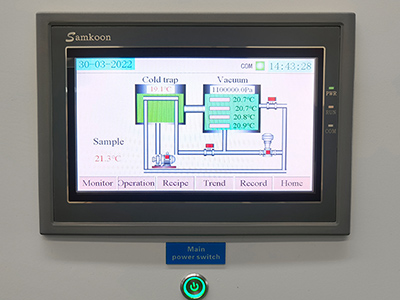

- 3. LCD touch screen, one button start. PLC system control, can set up programs and save different freeze drying formulas, one touch to run setted program for different samples.

- 4. USB interface can download freeze drying data for record.

- 5. Sturdy and stable universal wheel, easy to move.

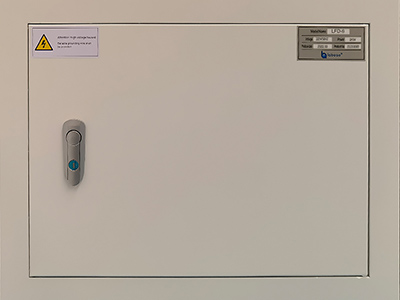

- 6. One touch to open the control box, easy to maintenance.

- 7. Includes an included stable and reliable vacuum pump.

DESCRIPTION

Lyophilization or freeze drying is a process in which water is removed from a product after it is frozen and placed under a vacuum, allowing the ice to change directly from solid to vapor without passing through a liquid phase. The process consists of three separate, unique, and interdependent processes; freezing, primary drying (sublimation), and secondary drying (desorption).

FEATURES

1. In-situ pre-freeze drying.

2. Temperature adjustable, controllable production process.

3. 30 sections can be set, the freeze dryer can modify the program parameters during the running process, and record the vacuum drying curve and data online.

4. Touch screen, you can set the power-on password to display the drying curve.

5. The square tray is not easy to be deformed, easy to operate and easy to clean.

6. The drying chamber adopts a high light transmissive colorless transparent plexiglass door, which can clearly observe the change process of the material during the operation.

7. Optional configuration of the inflation valve, which can be filled with dry inert gas.

SPECIFICATIONS

|

Model |

LFD-10 |

|

Freeze-dried Area |

0.92m² |

|

Handling Capacity |

10~12Kg/Batch |

|

Cold Trap Temperature |

<-35℃(No-load) |

|

Maximum Ice Capacity/Water Catch |

6.0kg |

|

Layer Spacing |

38mm |

|

Tray Size |

430mm*265*25mm 8Pcs |

|

Ultimate Vacuum |

15pa(No-load) |

|

Vacuum Pump Type |

2XZ-4 |

|

Pumping Speed |

4L/S |

|

Noise |

64dB |

|

Power |

2500W |

|

Power Supply |

220V/50HZ or Custom |

|

Weight |

130Kg |

|

Dimension |

640*680*1180mm |